I’ve titled this piece without a question mark, because I think I know what’s happening. Perhaps arrogantly. But if I ask it as a question, then I’m just being disingenuous.

I think it’s clear what’s happening with Boeing, and maybe you will too after reading this. Or maybe you won’t. I hope some of you disagree, and that you comment if so.

First, let’s dispense with any does-he-just-hate-Boeing curiosities.

I logged more than 3,000 hours in the C-17, a Boeing aircraft (albeit designed by McDonnell-Douglas).

It was a fantastic jet. I loved it. I trusted it. More times than I care to admit, I emerged from episodes of dubious piloting with my career and dental work intact because of the incredible quality of my trusty Boeing steed.

My wife worked for Boeing. Twice. She was trained and employed by Boeing. I drank beer with her wages. I drank whiskey with her wages. We went to concerts on her wages, and without them I never would have seen Maroon 5, being elementally opposed to buying those tickets with my own money.

I own Boeing pens, apparel, mementos, and even a decent baseball cap. The one with a Velcro adjustment, which in my world qualifies as high society.

I’ve got no shortage of love for Boeing. Which is why I even bother taking an interest in its unfolding story, which may in the end turn out to be just another example of corporate greed and stupidity running amok and ruining something beautiful. I hope that won’t be. But it’s the hope that kills you.

For decades, Boeing made the best commercial aircraft in the world. You should never feel a twitch of hesitation about putting your family aboard a Boeing jet.

But we want it to stay that way, which it might not do on its own. So we have to pay attention.

Something I learned at Amazon was that if you really want to fix something, you have to dig under the surface and find out what’s really driving it.

A great technique for this is Five Whys. Ask why something happened, then ask why the answer happened. Keep asking until the next answer doesn’t advance your understanding. You’re at or near the root cause. Address that, and you address the problem.

This works with basically anything. Today the thing on my radar is Boeing.

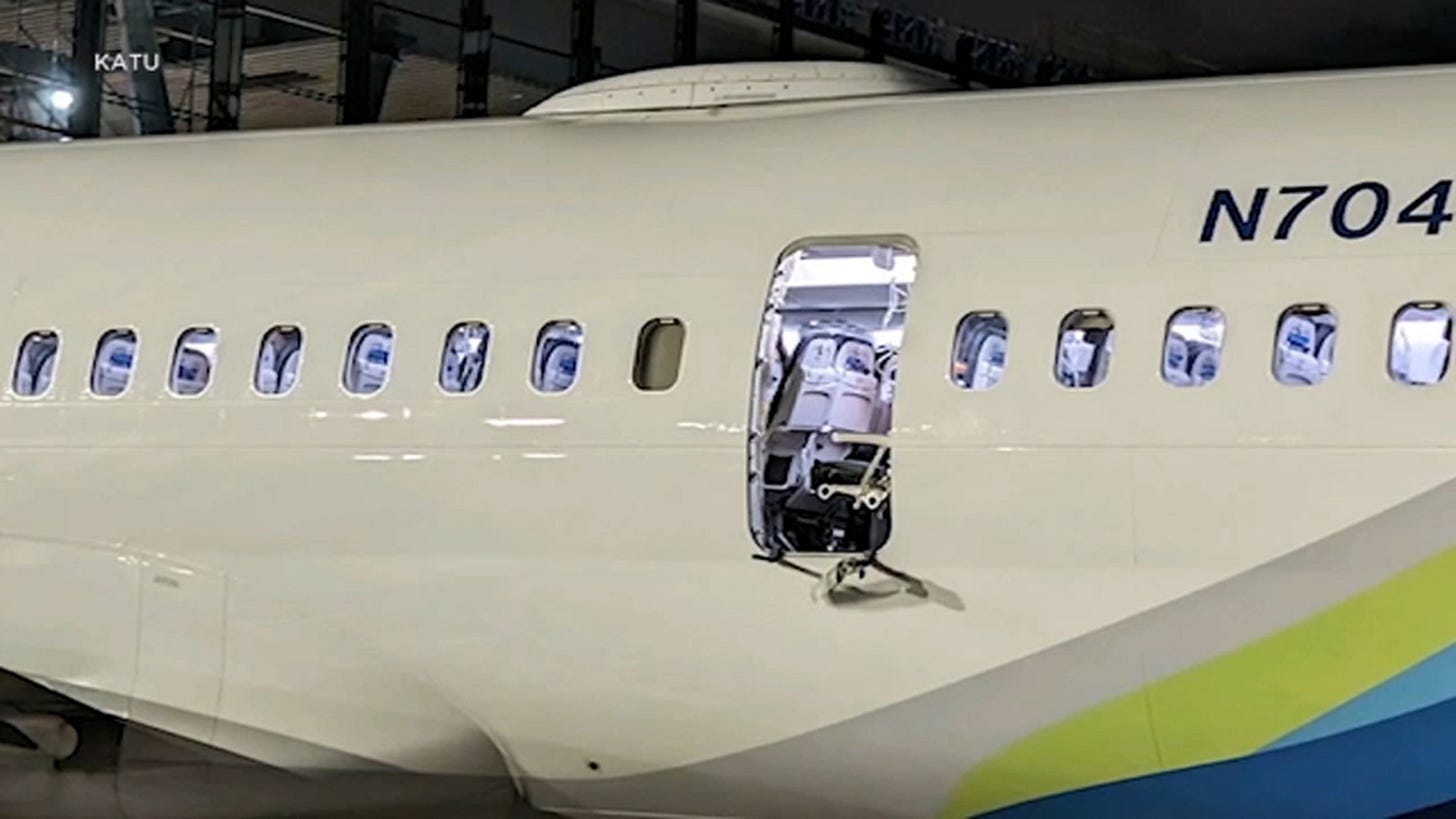

Earlier this month, as you probably heard, a Boeing 737 Max 9 operated by Alaska Airlines depressurized at 16,000 feet and made an emergency recovery after a door plug blew off in flight. It is miraculous no one was hurt, and the outcome almost certainly would have been much worse if it had happened mere minutes later, at a higher altitude.

In the ensuing investigation, it’s becoming clear the issues suspected in this failure are more widespread than the involved aircraft, and in fact trace to the design and manufacture of multiple 737 variants. While we don’t have conclusions yet, it appears Boeing will have some ‘splaining to do.

It’s not the first time in recent years that pilots, airlines, the FAA, politicians, and the flying public have had cause to look upon Boeing with a jaundiced eye.

It was only 5 years ago that nearly 350 people were killed in a pair of 737 Max 8 crashes which were eventually attributed to manufacturing issues. The Max 8 was grounded for 20 months. As the situation unfolded, it became clear Boeing had known about risks in the design but not properly acted upon or shared knowledge of them.

In 2021, after investigations and public pressure eventually nullified its denials and obfuscations, Boeing signed a $2.5B settlement with the Department of Justice to close a fraud and conspiracy probe into the Max 8 debacle.

And debacle is the right word.

When the Max 8’s safety risks were exposed, Boeing went on a PR blitz, reassured shareholders and the flying public, conducted a bureaucratic shuffle, infused a few new acronym-laded gimmicks into its business model, lobbied government, and went back to what it was doing before.

This continued a pattern aged over decades.

My fear is we will see the same pattern again with the Max 9’s door issues. Boeing’s CEO may be ritually sacrificed, albeit with millions of go-away cash heaped atop the $66M pile he’s collected the past few years. But almost certainly this would be a proxy for genuine reform rather than an element of it.

We don’t know the answers to the door saga yet. But I’m willing to bet that whatever’s driven this new issue will rhyme with what drove the Max 8 catastrophe. Because Boeing’s conduct since the door plug incident convinces me not much has changed since it persuaded the government to take a payoff rather than prosecute executives.

And that makes revisiting the Max 8 worthwhile.

Let’s do so in Five Whys format.

Why 1: Why did 737 Max 8 crashes happen?

Because of design-driven software malfunctions pilots were not trained to handle, leading to inadequate emergency responses and irrecoverable stalls.

Why 2: Why weren't the pilots trained to deal with it?

The idea of 737 Max was to field a platform occupying the same market segment as the legacy 737, but with better range, payload, and fuel efficiency.

In order to save on research and development and speed the solution to market, the decision was made to build on the well-established and successful foundation of the 737 rather than design a new aircraft.

Achieving the design goals with a modified 737 airframe meant giving it bigger engines and a longer fuselage, the combination of which meant the engines were mounted more forward on the wings, which changed the aerodynamic performance of the aircraft.

But to avoid the costs of constructing simulators and retraining pilots, Boeing directed a redesign of the flight control system. To mitigate the elevated stall risk created by the new aerodynamic profile, Boeing introduced a software modification to automate and sub-automate some flight control inputs. It was called Maneuvering Characteristics Augmentation System (MCAS).

MCAS was poorly engineered. It malfunctioned, creating uncommanded nose-down movement which resulted in the total losses of Lion Air Flight 610 and Ethiopan Airlines Flight 302, along with the deaths of 346 people.

Many believe the flaw relates to a decline in Boeing’s engineering standards, with MBAs ascendant to senior roles and a corporate culture replacing its traditionally scientific culture.

Why would Boeing avoid a new design if it meant taking this risky path?

Because Boeing has recognized innovation is expensive, and it will make more profit by adapting existing designs. The company has no plans for new commercial models, and its most recent airliner design is two decades old.

This is related to a lack of industry competition. The commercial aircraft manufacturing business has consolidated and condensed into a duopoly, with Airbus as Boeing’s only competitor for new sales.

Companies that lack competition struggle to keep a sharp edge. They lose hunger. Eventually, their lethargy metastasizes, killing the founding mindset that made them great. They start obsessing over costs, avoiding risks, and promoting bureaucrats. Take a look at Amazon, my former employer, for an example of a company which lacks competition and is starting to exhibit the symptoms.

Without competition, there is no commercial incentive to take risk. The corporate approach shifts to avoiding unnecessary expenses and instead squeezing revenue out of existing products and services. This is a contraction mentality, and is antithetical to the spirit of growth which drives smart engineering.

Why does Boeing need external competition to innovate?

Boeing’s corporate culture shifted radically after its 1997 merger with McDonnell-Douglas, which had a stronger focus on military aircraft development and a bureaucratic culture to match.

Engineers felt the post-merge shift to obsessing over share price and profit margin drowned out their voices. This is reflected in how company performance changed across that time.

The 777, fielded by Boeing pre-merger, was an exceptional design. It set a new bar as the world’s largest twin-engine airliner, with a combination of range, technology, handling, and fuel efficiency that would make it the most popular wide-body jet ever made. Boeing built and delivered the 777 on time, feeding and enlarging a warm market for a clearly superior product.

Now let’s talk 787, the first (and last) commercial design after the merger. Needless to say, it didn’t go as well.

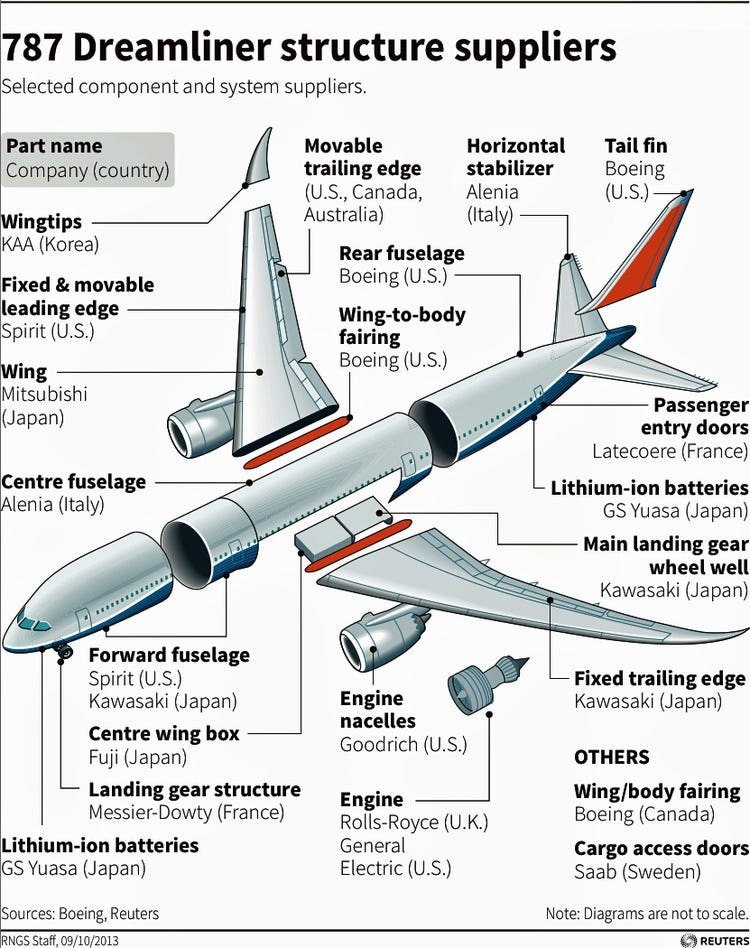

Seeing an opportunity to increase profit margins, executives decided to outsource the majority of 787 manufacturing. The plan was to sub-assemble at various plants around the world and then ship the sub-assemblies to Boeing’s South Carolina and Washington facilities for final assembly.

This meant labor and material costs could be discounted enough to more than compensate for transportation expense, resulting in a cheaper cost basis. Boeing essentially positioned itself less as a manufacturer and more as a supply chain management firm, because that’s where it saw the commercial opportunity.

This approach meant the 787 would be the first Boeing jet majority built by non-US subcontractors. When you ride in or fly a 787, you’re technically flying a foreign product, which creates an interesting juxtaposition with Boeing’s America-first branding.

But this novel strategy didn’t work. As anyone with a lick of sense could have predicted, distance from an operation impairs quality control, which is a huge issue anyway but carries more risk in a lowest-bidder subcontracting model.

Boeing found itself trying to mate together bits of an aircraft that had not been made properly to spec, and in the process also uncovered flaws in its underlying design. Engineers found themselves lugging their drawing boards to the production line to literally re-design the 787 in the stride of building it.

The result was a project delivered 5 years late and roughly $15B over budget. Demand was dampened, along with investor confidence.

This should have signaled Boeing to rush back to its scientific value system and engineering foundations. But we can see now that it simply abandoned trying to make new airliners, turning instead to the more profitable practice of cannibalizing existing designs, training routines, and supply chains.

How does a company this badly-run survive?

Lack of competition helps. The reality of a duopoly also helps, given that neither party has an interest in seeing the other fail, which would create a monopoly harmful to everyone’s interests. There is no competitor positioned to deliver a killing strike to a wobbly Boeing.

But the most important reason is its relationship with the US government.

The government sees Boeing as an essential American symbol, employer, and institution. Boeing’s global profile is an element of American commercial power. Sub-contracts and associated businesses feeding Boeing’s production lines represent the livelihoods of hundreds of thousands of workers in every state in the union. Its overseas business connects to diplomatic relationships and is not irrelevant to foreign policy objectives.

And Boeing does a hell of a lot of lobbying to reinforce all of this. Notice in the chart below how the timing of a massive leap in its material lobbying commitment coincides with the fielding of its last original airliner design. Boeing has obviously concluded that it will get a better return on investment from influencing politicians than it will by creating new advancements in aeronautics. This reflects a seismic shift in corporate strategy.

Together these realities explain why Boeing gets government help hocking its wares abroad.

Why government guarantees the commercial loans that power Boeing’s activities.

Why it keeps getting military contracts even after scandals expose its difficulty undertaking legal and ethical obligations.

Why, even after it demonstrates lethal failures to adequately oversee its own activities, the FAA continues to delegate compliance enforcement to Boeing.

Boeing is too big to fail. This is the root cause.

And this, I believe, explains the Max 8 fiasco.

It is also totally intractable. It won’t self-solve.

I was a passenger on a Boeing 787 the day before the door plug incident happened. I was a passenger on a Boeing 777 the day after. I will continue to be a passenger on Boeing jets. Admittedly a passenger of poor disposition, as many pilots tend to be, who gulps wine as a countermeasure.

But at the same time, I and we have something we should consider in stone sobriety.

And it’s that executives generally don’t give a toss about what happens later. They exist to translate activity into money. They make choices safe in the knowledge they’ll be wealthy enough to defend themselves, have moved along, and in fact will probably be dead or too old to care when the consequences of the risks they masked to maximize profit are exposed. Most often, they are correct.

We cannot depend on Boeing executives to ensure we will all continue to be safe and feel safe aboard Boeing commercial aircraft into the future.

So we have to exert our modest individual influence to urge the government to change its relationship with Boeing. To put the pin back in the “too big to fail” grenade before it explodes. Because we need this company to do better. The things that place it at risk also make it an essential and indispensable linchpin of American commerce, and indeed a big thread in our national culture.

There are some early indications that the FAA response to the Max 9 door issue will be different, and that Boeing may lose some self-policing latitude. But I’m not sanguine.

It would be a tragic shame if we need to learn this particular lesson the hard way. It’ll be measured in blood and pain.

But it’s on my radar. And now, on yours.

Written for every passenger and aircrew member who trusts Boeing to build safe products, and should be able to continue doing so.

TC is experienced in aviation, management culture, and flying operations. He is also an American veteran with hundreds of friends and family members working in the US commercial aviation industry, so his views and opinions in this article are unavoidably impassioned and consciously biased.

I won’t disagree with your thoughts on Boeing’s executive culture being more concerned about this quarters earnings reports and the current stock price. Boeing is no different in this regard than a significant, and growing number of other large American corporations.

I do think you are missing a key piece in your assessment of why Boeing choose to refresh a decades old design vs coming up with something new, however. Boeing’s customers did not and do not want a new design. Southwest, and the other major 737 carriers lobbied Boeing and the FAA to ensure that the next generation aircraft would share a common type rating and thus a common training infrastructure with their current fleet. A fancy new mid-range aircraft with all the latest bells and whistles, while possibly more comfortable, easier to fly, and safer would necessitate a loss of the economies of scale and all of the other benefits of a single (or limited) fleet. Like almost all manufacturers, Boeing is producing the product that its customers want to buy.

I hope this story ends differently, and that Boeing can restore itself as a leader in the world aero market.... but just add you failed to present a rosy conclusion, I am also unable to see this as a realistic outcome. Without dead Americans involved, I think this one will disappear. Boeing hands politicians money, and politicians will again hand Boeing a pass.